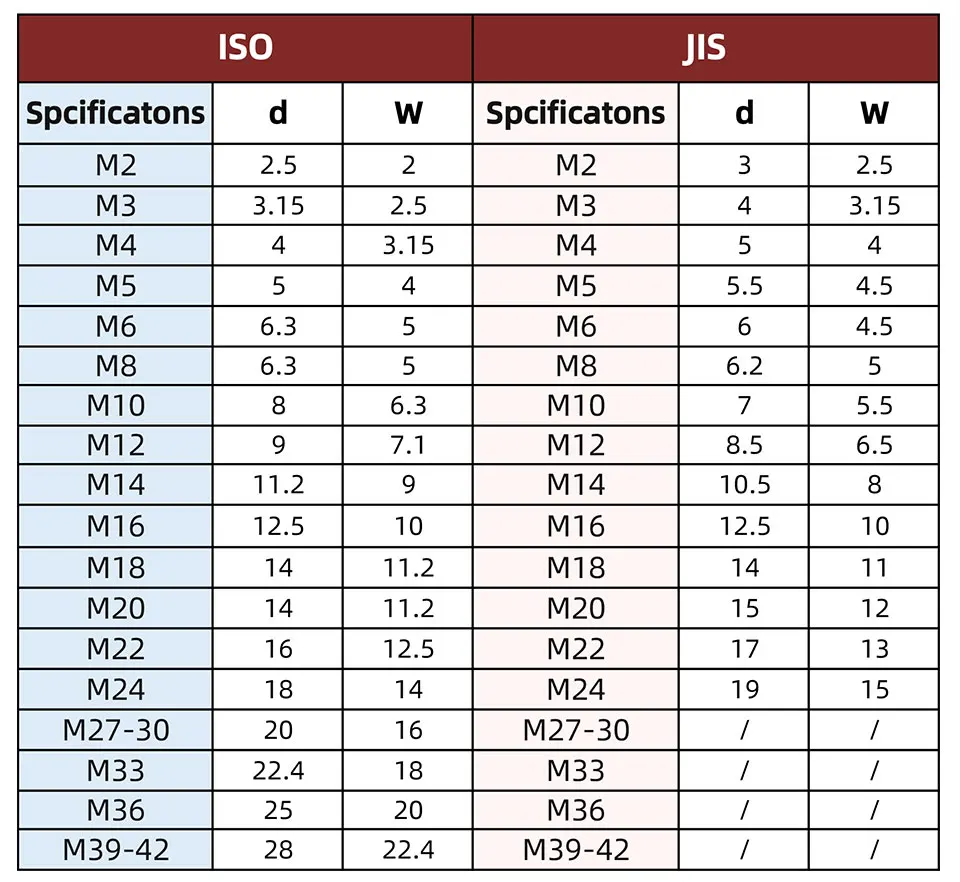

SPECIFICATIONS

Brand Name: BB

Origin: Mainland China

Diameter: M3,M4,M5,M6,M8

Model Number: ERG

Material: Steel

Type: Tap

AA: 0.008

Precision Grinding High Precision and Stability

The workmanship is fine, the surface is exquisite, and the overall precision is high

Accuracy ≤ 0.008mmMartensitic Structure Reinforced Heat Treatment

Effectively maintains precision to avoid deformation and cracking

65Mn Alloy Spring Steel

High elasticity, strong steel properties, breakthrough elastic constraints for stable cutting, greatly improving the service life

Clamping Force is Tight

Elastic Force is StrongSuper Strong Clamping Force Stable and Does Not Loosen

Enhanced clamping force, good elasticity for lasting stability, ensuring exceptional precision

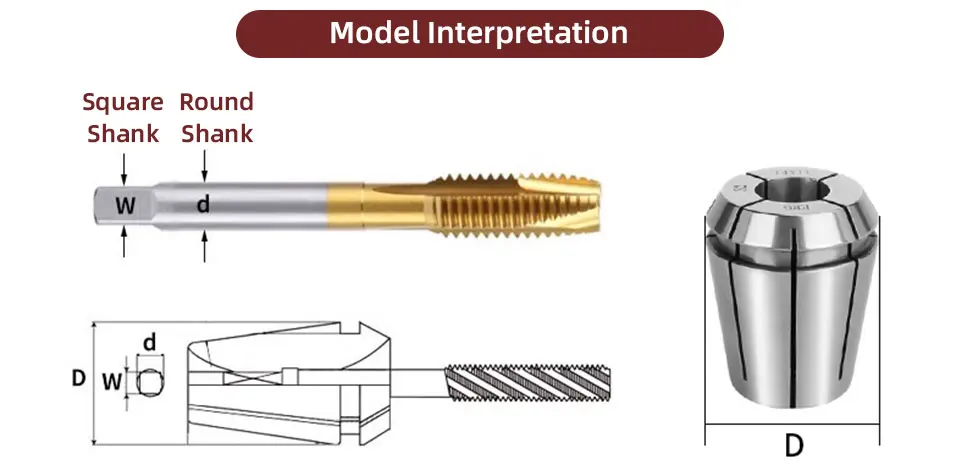

Square Hole at The Tail Stable and anti-Slip

The square hole at the tail locks tightly, preventing the tap from slipping

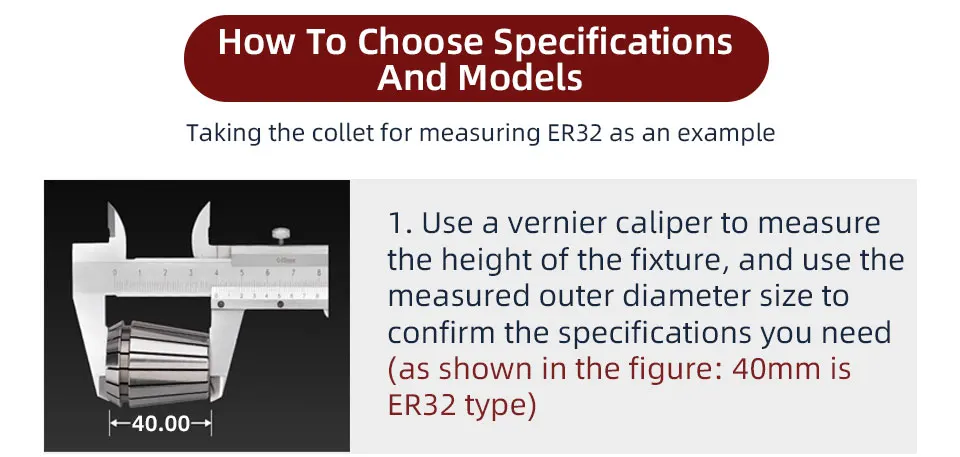

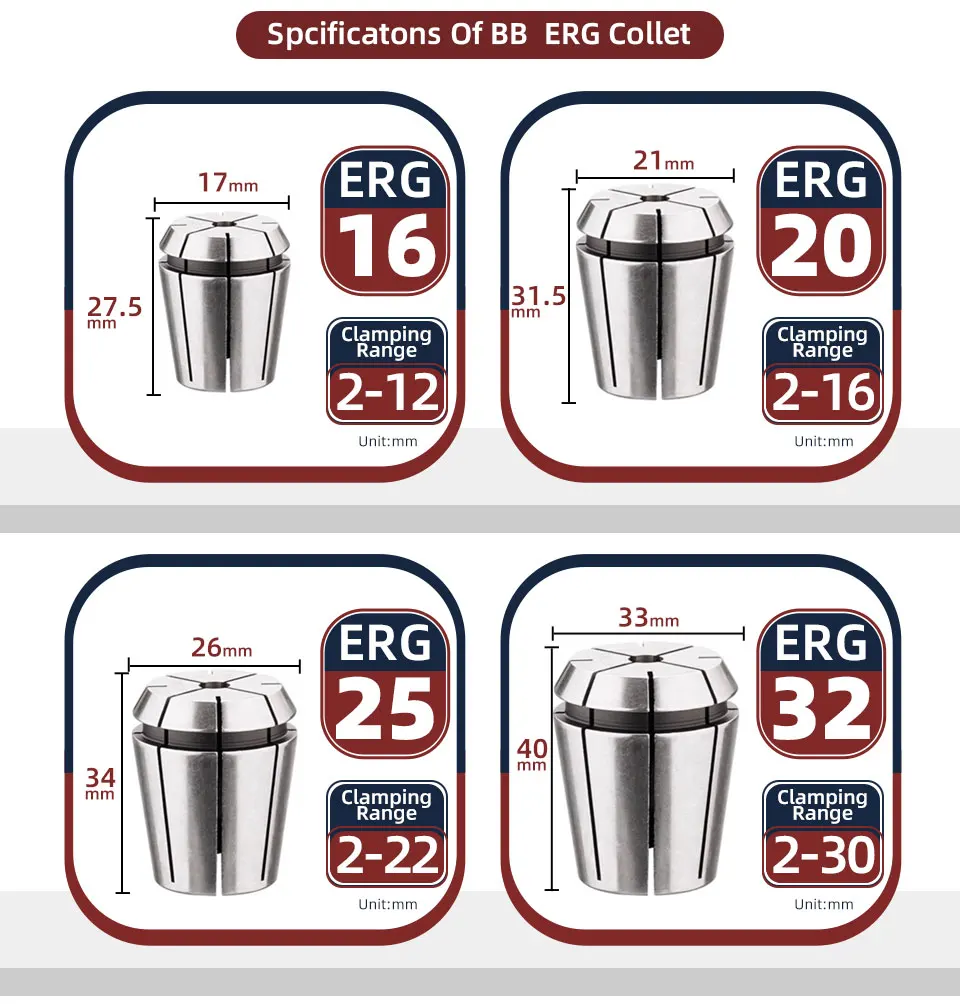

How To Choose Specifications And Models

1. Use a vernier caliper to measure the height of the collet, and use the measured outer diameter size to confirm the specifications you need (as shown in the figure: 40mm)

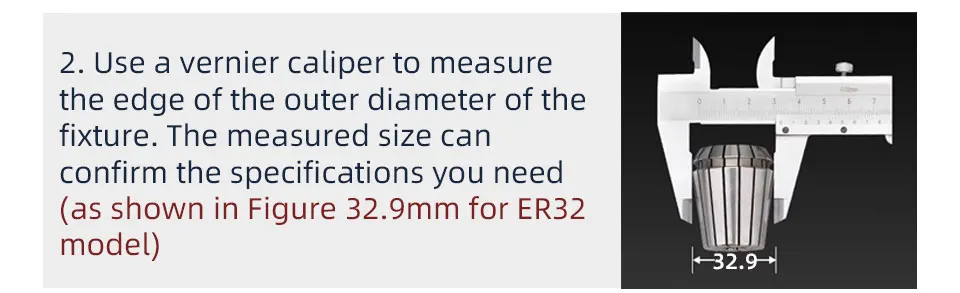

2. Use a vernier caliper to measure the edge of the outer diameter of the fixture. The measured size can confirm the specifications you need (as shown in Figure 32.9mm for ER32 model)

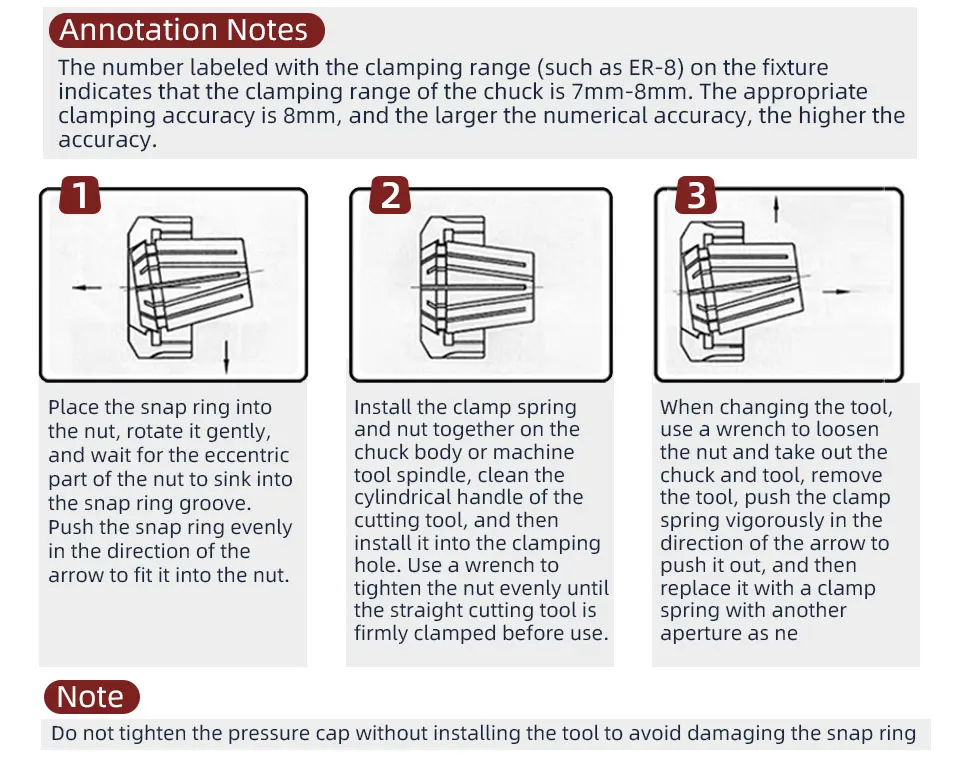

Annotation Notes

The number labeled with the clamping range (such as ER-8) on the fixture indicates that the clamping range of the chuck is 7mm-8mm. The appropriate clamping accuracy is 8mm, and the larger the numerical accuracy, the higher the accuracy.

1.Place the snap ring into the nut, rotate it gently, and wait for the eccentric part of the nut to sink into the snap ring groove. Push the snap ring evenly in the direction of the arrow to fit it into the nut.

2.Install the clamp spring and nut together on the chuck body or machine tool spindle, clean the cylindrical handle of the cutting tool, and then install it into the clamping hole. Use a wrench to tighten the nut evenly until the straight cutting tool is firmly clamped before use.

3.When changing the tool, use a wrench to loosen the nut and take out the chuck and tool, remove the tool, push the clamp spring vigorously in the direction of the arrow to push it out, and then replace it with a clamp spring with another aperture as needed.

Note:

Do not tighten the pressure cap without installing the tool to avoid damaging the snap ring

top of page

bottom of page