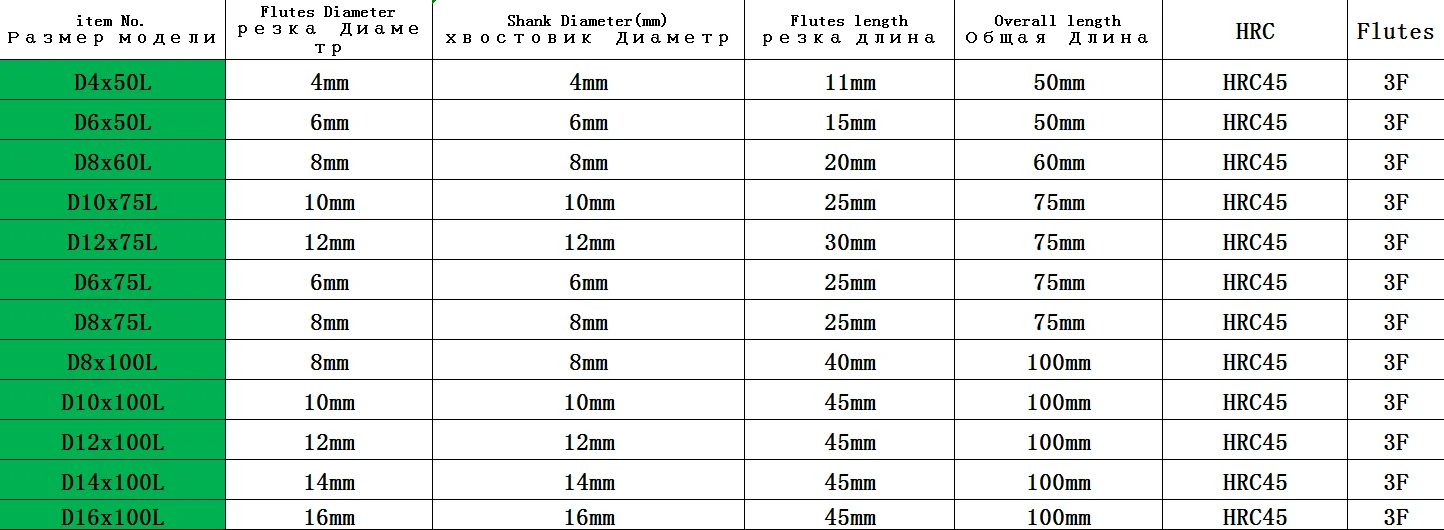

SPECIFICATIONS

Brand Name: JERRAY

Origin: Mainland China

Overall Length: 50-100MM

Material: Tungsten Cobalt Alloy

Type: Roughing End Mills

Certification: none

Diameter: 4-16MM

Coating: TIAIN

HRC: 45

Material: Tungsten Cobalt Alloy

Flutes Diameter: 4-20MM

Shank Diameter: 4-20MM

Flutes: 3 Flutes

Flute Length: 11-40mm

Overall Length: 50-100mm

The picture only for reference.

please check the item No.

A rough milling cutter, also known as a roughing end mill or rougher, is a cutting tool specifically designed for the initial, heavy material removal phase of machining processes. These tools are typically used in milling machines and machining centers for efficiently removing excess material from workpieces, leaving a rough surface finish that will be further refined in subsequent machining operations.

Key features of a rough milling cutter include:

1.High Material Removal Rate: Rough milling cutters are engineered to remove a large volume of material quickly, making them ideal for bulk material removal tasks.

2.Robust Design: These cutters are built to withstand the high cutting forces associated with heavy material removal, ensuring durability and longevity.

3.Coarse Teeth or Flutes: The teeth or flutes of a rough milling cutter are designed with a more aggressive geometry, allowing them to effectively shear through material.

4.Reduced Heat Build-Up: These tools are designed to efficiently evacuate chips and reduce heat generation during the cutting process, which helps extend tool life.

top of page

bottom of page