SPECIFICATIONS

Brand Name: BLP

Hign-concerned Chemical: none

Origin: Mainland China

Model Number: HRC50

Overall Length: Regular Length

Material: Carbide

Type: Face Mill

Certification: none

Diameter: 1.0mm-20mm

Coating: AlTiN

Certification: BLP

Overall Length: Regular Length

Diameter: 10mm-20mm

Coating: AlTiN

Origin: Mainland China

Model Number: HRC50

Type: Face Mill

Material: Carbide

Machining Center: NC machiningCNC machiningEngraving machineHigh speed machine

Working Conditions: FinshingSemi-finshingRoughing

Mill Diatolerance: -0005-0

Shank Diatolerance: H6

Cutting material 1: Garbon steelsalloy steelstool steelsalloy steels

Feature 1: General Purpose Carbide Endmills

Feature 2: Milling Cutter For Metal

Feature 3: Alloy Coating Tungsten Steel Tool

Feature 5: Wholesale Top Hardness Kit Milling Machine Tools

Hardness: HRC50(Coating Position)

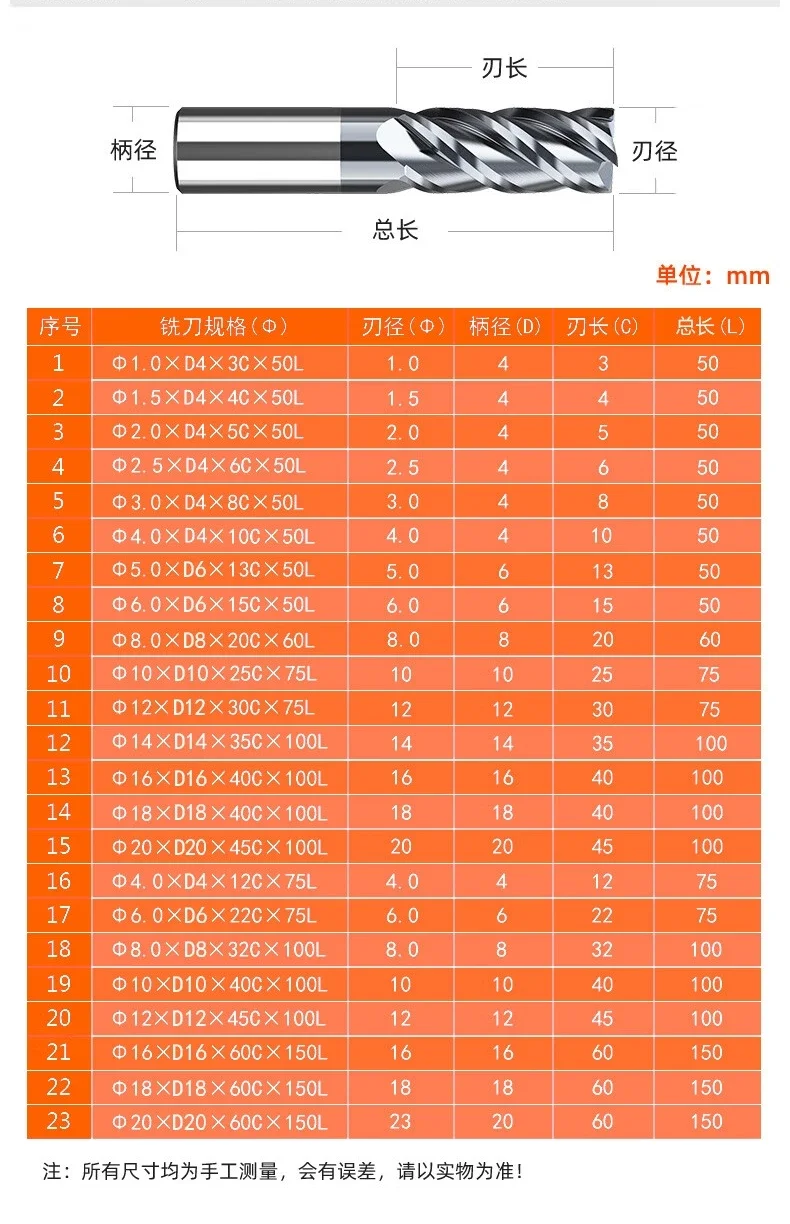

Cutter Parameters: Shown On Details Page

Cutting material 2: PlasticWoodStoneleatherSteelIron

Coating Hardness: 3600HV

Nano-coating Thickness: 02Mu

Product characteristics

Product Name: HRC50-4-Flute Flat End Mill

Blade diameter range: 3.0-20mm

Full length range: 50/60/75/100/150Lmm

Coating: Nano coating

Tool raw material: imported wear-resistant hard alloy, fine particle tungsten steel 0.6 μ M particles

Applicable processing material hardness: HRC35 ° - HRC50 °

Applicable processing materials: Die steel, tool steel, quenched and tempered steel, carbon steel, cast iron, etc

Customization or not: Support non-standard customization

Product features: good rigidity, high wear resistance, high processing accuracy, short delivery time, commonly used in forming processing to save tool costs and improve processing efficiency. The smooth cutting effect can reach up to 10 hours

Product advantages:

1. The fine particle tungsten carbide base material has high toughness and is covered with a nano coating, which is wear-resistant.

2. Large capacity chip removal, fast chip removal, and difficulty in sticking the tool achieve efficient processing, and the workpiece is high-precision and shiny.

3. Dedicated to CNC milling machines for high-speed pin cutting, it can increase smoothness, reduce wear coefficient, reduce tool changes, improve machine efficiency, and save workpiece production time.

4. Balanced cutting force eliminates uneven feed and is more conducive to machining.

top of page

bottom of page