SPECIFICATIONS

Brand Name: MZG

Origin: Mainland China

Model Number: P3202-D08(R4) ZP35

Material: Carbon steel

Type: Ball Nose End Mills

Certification: none

Diameter: 8

Coating: None

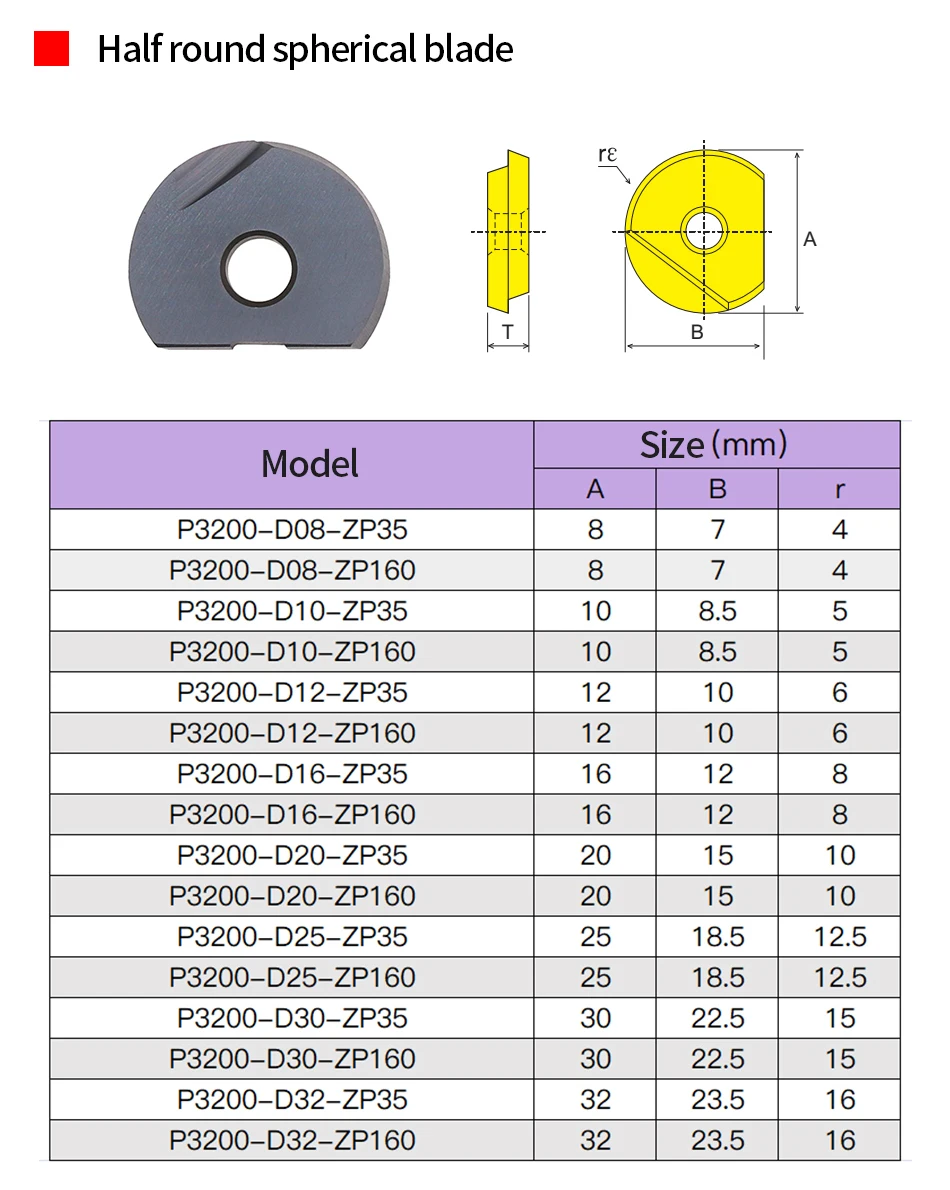

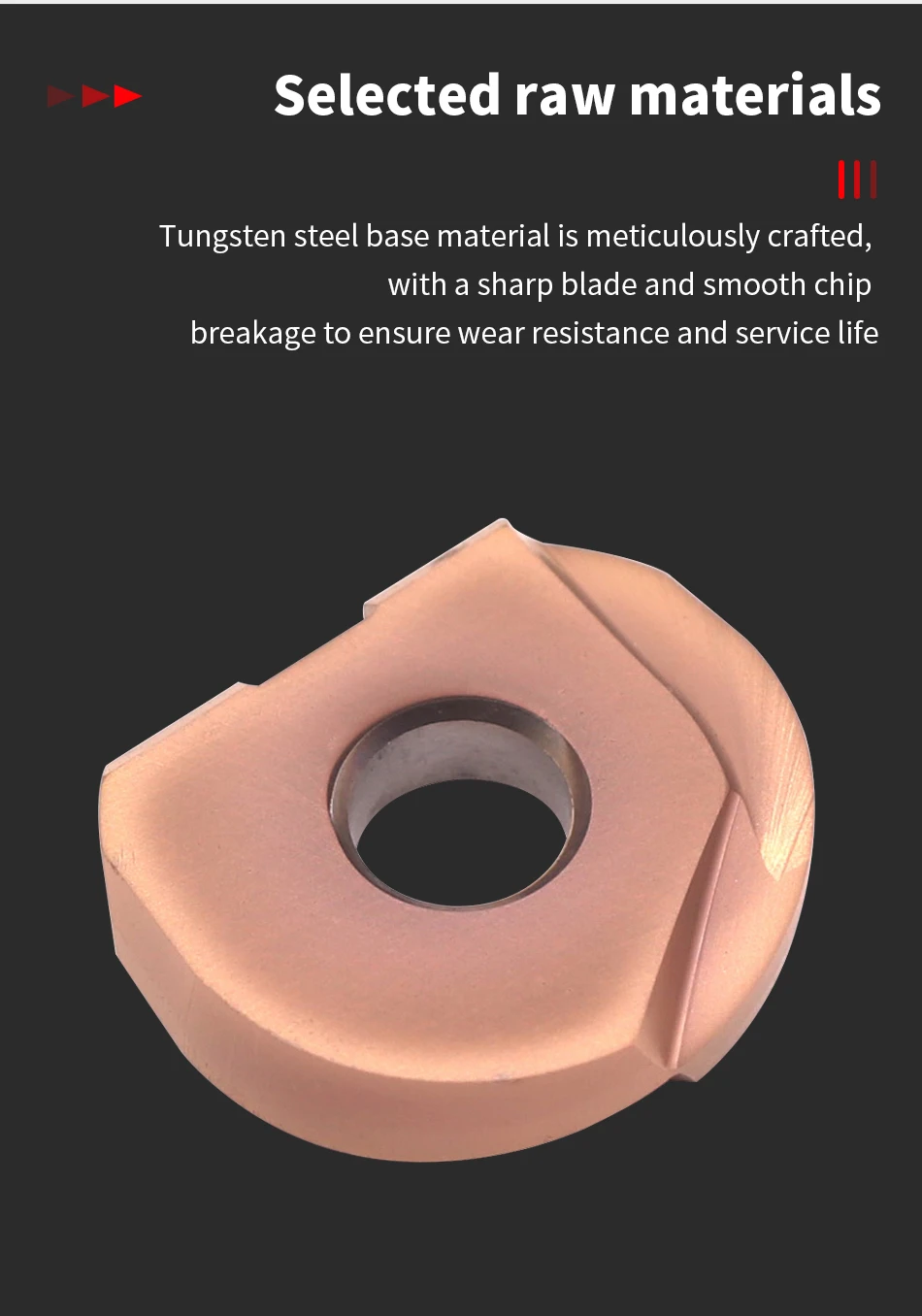

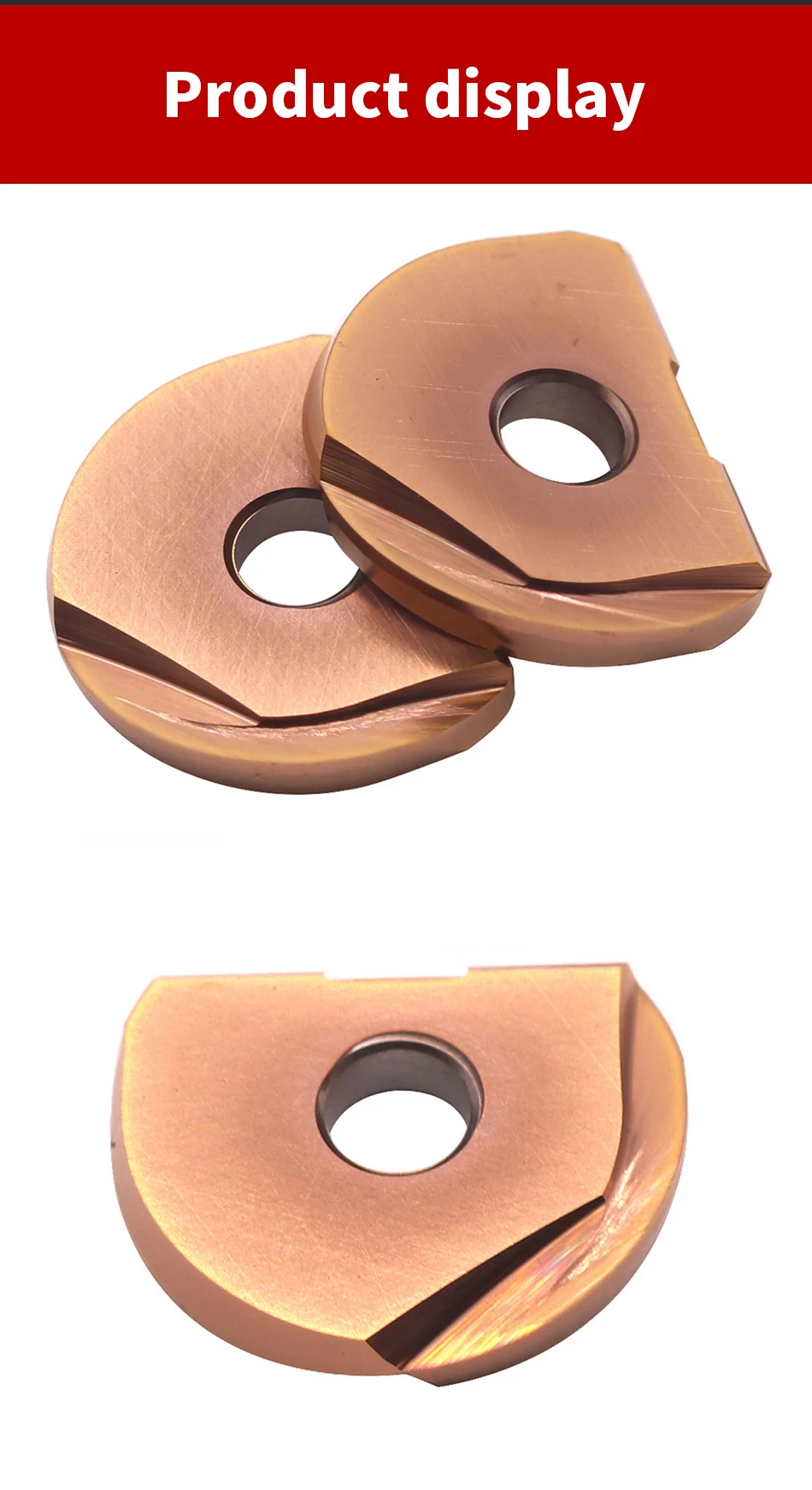

MZG 10PCS P3200 P3202 D10(R5) ZP160 ZP35 Steel Processing Fast Feeding Cutting Milling Cutter Machining Carbide Inserts

4.MZG Tungsten Carbide Inserts Parameter

MZG CNC Tool Insert Material Introduce

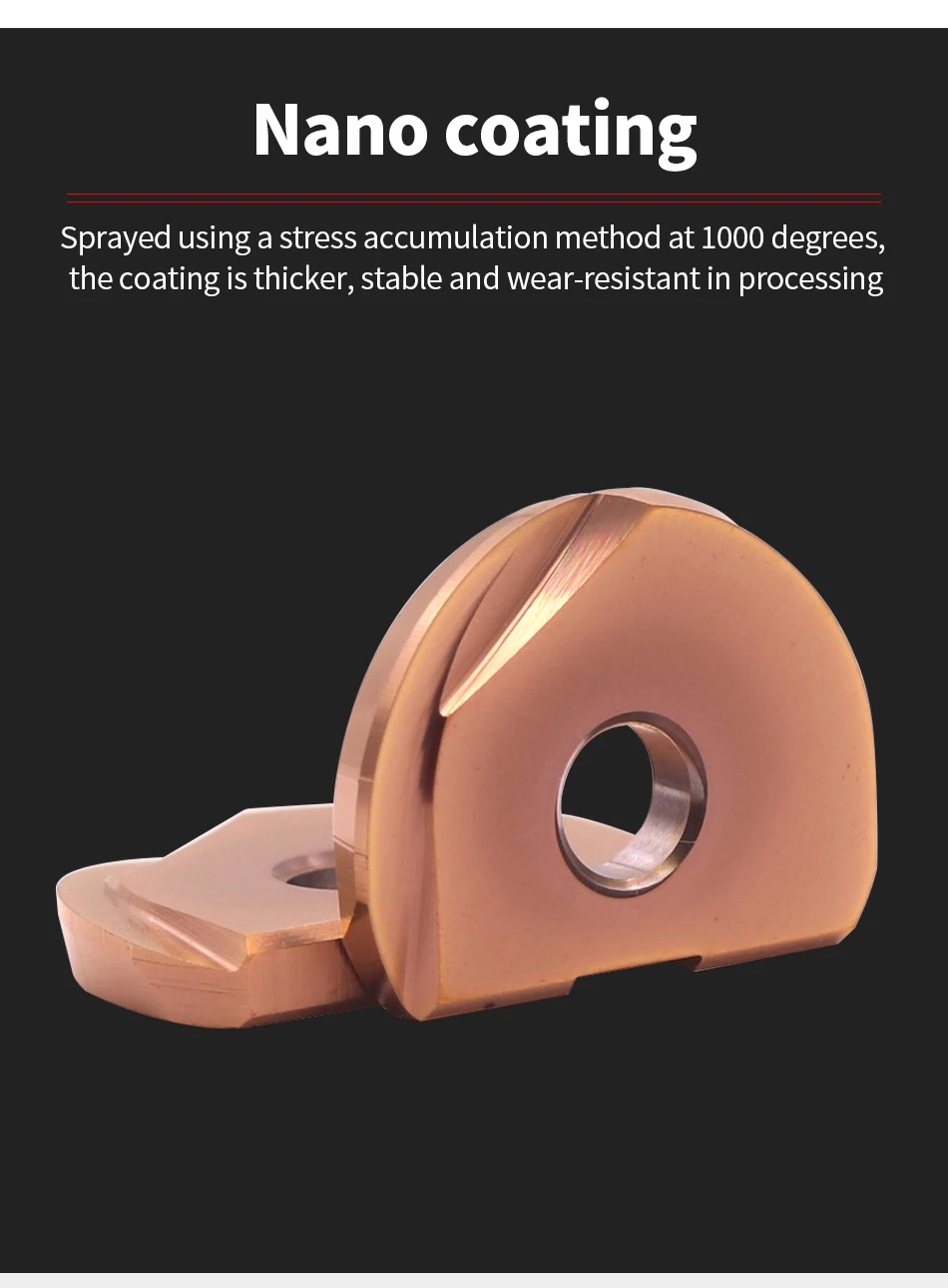

1.Coated Carbide(CVD)

Applicable from low to high speed cutting and from finishing to roughin.

Stable cutting is achieved due to the superior toughness and crack resistance.

Cutting times are reduced due to good chip control from effective chipbreakers.

Achieving superior processing efficiency in the field of a wide range of steel/casting Parts processing.ZC2501 ZC2502 : suitable for low speed machining of steel partZC2511 ZC2512 : suitable for high speed machining of steel partZK3511S : suitable for hihg speed machining of cast iron part2.Coated Carbide(PVD)

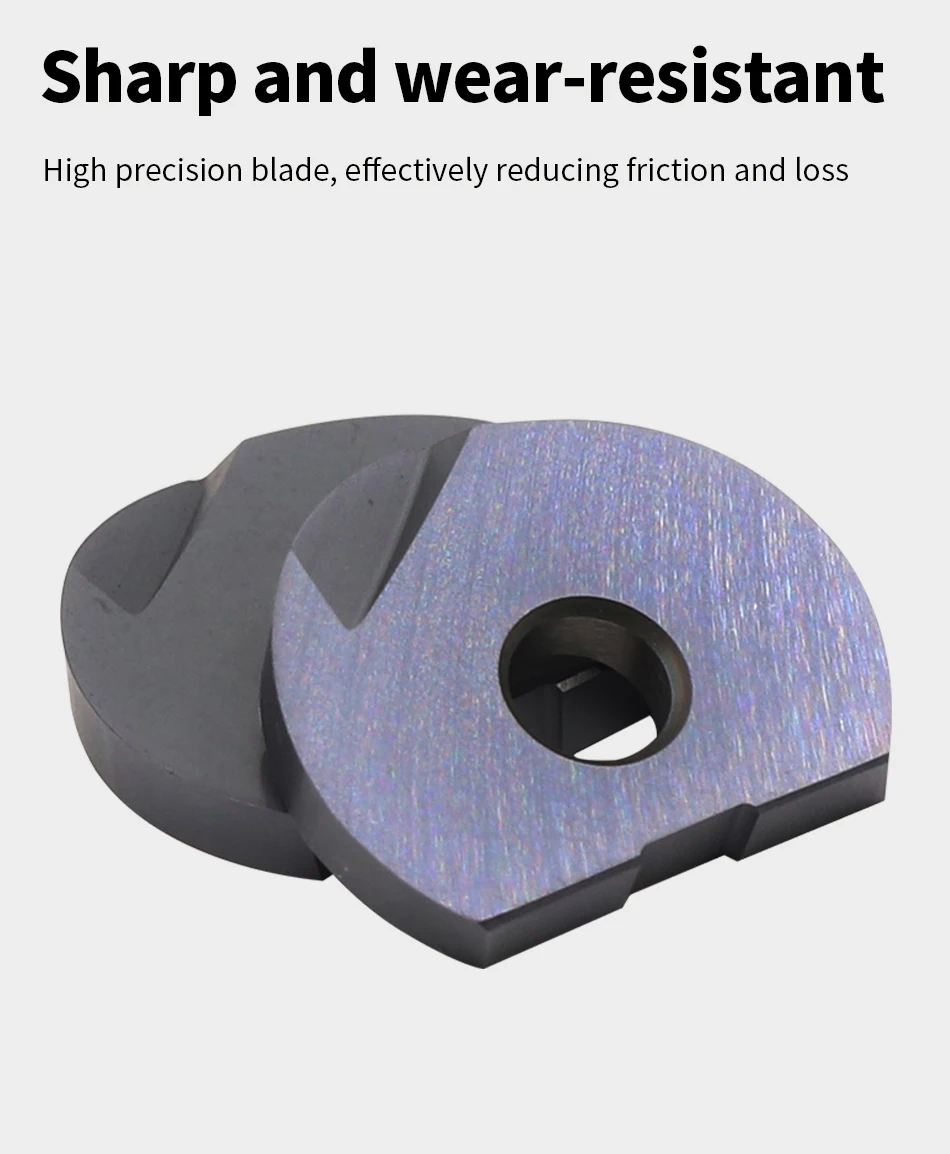

Good for low to high speeds and finishing to heavy roughing cutting.

Stable cutting with excellent toughness.

Smooth fine surface of PVD coated carbide provides good surface finish and high.

Achieved high reliability in the unstable processing field of stainless steelZP1521 : suitable for high speed machining of stainless steel3.Cermet

Excellent wear resistance enables high cutting speeds

Cermet maintains good surface finished due to the low affinity to workpiece material.

Excellent wear resistance enables high cutting speeds.

ZN60 : suitable for steel/cast finish processing4.Carbide

Tough and Hard, good thermal conductivity

Suitable for cutting non-ferrous metals and non-metals

Stable cutting at low cutting speeds, including milling operations

ZK10 : suitable for Cutting Aluminum Al non-ferrous processing5.CBN

Superior wear resistance when cutting hard materials

Suitable for high speed cutting of cast iron and sintered steel

High thermal conductivity provide stable cutting

CBN-S : suitable for difficult cutting material processingCBN-K : suitable for cast iron processing6.PCD (Diamond Sinter)

Applicable for non-ferrous metals, non-metals turning milling and other various type of cutting .

Reduced edge build-up allows for high precision cutting.

Diversified applications for cutting of non-ferrous metals and non-metals.

Finished surface will be rainbow colored.(a mirror-like finished surface will not be obtained when single crystal diamond is used.)

top of page

bottom of page